Product Description

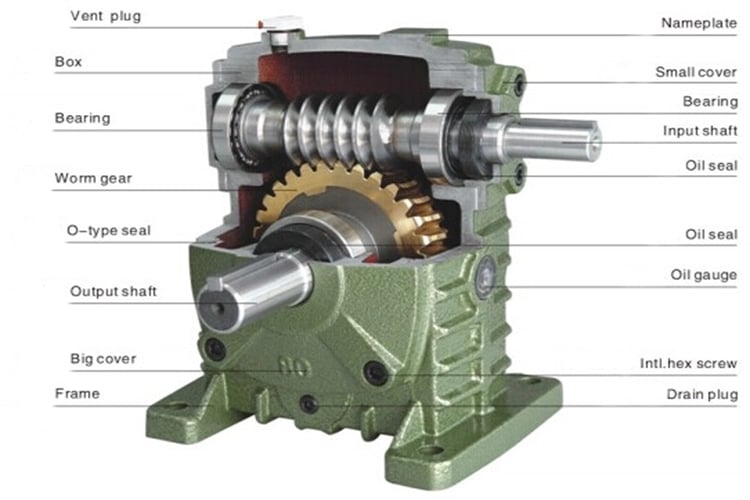

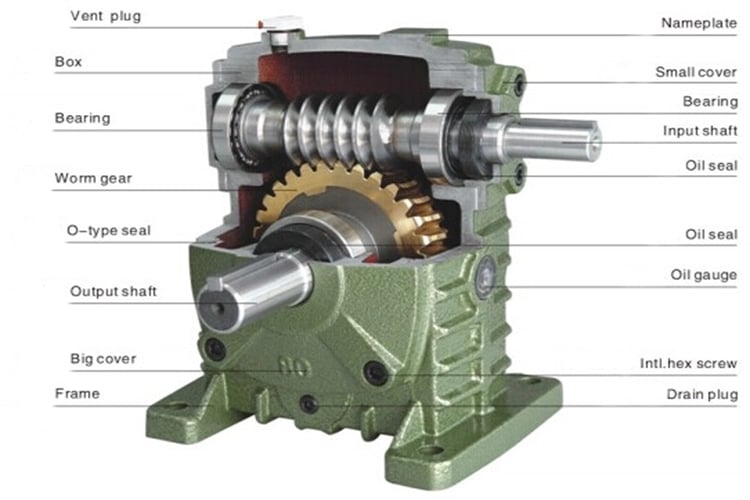

Worm and Wheel Gear Diameter Shafts Pin Nylon Bore Tooth Brass Stainless Steel for Speed Motor Reductions Transmission Parts High quantity Aluminum Worm Wheels

The mating worm gear mounts on a specialized Steel 1/4″ D-Bore Barrel Hub for Worm Gear to create a reliable junction between the gear and the shaft it’s turning. The worm and the worm gear are designed so that you can run them 0.75″ apart from 1 another; the same spacing you’ll find on Ever-power and other components within the build system. Aside from the massive reduction in speed and the increase in torque, these worm gears will lock in place when at rest so you don’t have to worry about an outside force backdriving the mechanism driving them.

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Cast Steel |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

Safety Precautions For a PTO Shaft

When you are working around PTOs, be sure to observe several safety precautions. These include removing the shield, keeping a safe distance from the machine, and avoiding entanglement. Entanglement is a serious injury that can even lead to death. Workers who are near the machine should always maintain a safe distance, especially if the speed of the machine is fast enough to entangle clothing. The speed of the PTO is usually 540 to 1,000 revolutions per minute, and the speed is enough to cause injury in a split second.

Safety precautions

One of the most important safety precautions for a PTO shaft is to make sure that it is properly guarded at all times. An unguarded PTO shaft can entanglement a worker, cause an injury, or even cause death. Operator awareness is key in preventing this hazard. Among other things, workers should not make repairs while the PTO is in use or wear loose or frayed clothing when working near the PTO. Likewise, they should read and follow instructions provided with their tractor and implement. Finally, they should use PTO shafts only for their intended purpose.

Another important safety precaution is to wear a protective gear such as a helmet and gloves before operating a PTO shaft. This type of equipment can be extremely dangerous because of its speed. A PTO shaft that is rotating at 540 rpm can travel two metres in less than a second. Damaged shielding is a common cause of entanglement, so it is important to check your machinery for damage before operating it.

When operating a tractor, PTOs should be kept clear of loose clothing. Loose clothing can easily catch on a rotating PTO shaft. Long hair or jewelry can also become entangled in a PTO shaft. It is also important to remember to secure the PTO shaft guard when the tractor is not in use. Also, never engage a PTO when the engine is off.

Types of pto shafts

PTO shafts are used in tractors and other equipment to secure the secondary gear in the tractor. They are available in different styles and sizes. These shafts are designed to withstand pressure, impacts, and tension. They may also include a shear pin and slip clutch. Before buying a new PTO shaft, make sure to check its measurements.

There are two types of PTO shafts available in an Agric rototiller. The first one has a slip clutch and the other has a shear pin safety device. In order to identify the type of PTO shaft used in a particular tractor, it is important to understand what it is used for.

There are two types of PTO shafts: the external and internal. The latter is used for larger machines, such as a lawnmower. The former is suitable for agricultural applications and is the preferred type for large tractors. The former is suitable for plowing, mowing, and shredding.

Transmission PTO shafts are the oldest type of PTO. They are connected to the tractor’s transmission. When a tractor is in gear, it stops the PTO shaft. However, when it’s not, it’s ineffective and can pose serious problems, such as when mowing. This type of PTO can also cause an overrun clutch to prevent the PTO shaft from working properly.

Reaction time

It’s important to know your reaction time when working around a power take-off (PTO) shaft. This part of the machine rotates at approximately 540 revolutions per minute and can pull in seven feet per second. Reaction time can be affected by age, physical condition, medications, lack of sleep, and stress. If you’re working around a PTO, be sure to remove any loose jewelry or other items that might interfere with your reaction time.

PTO accidents can be caused by several factors. The operator, the machine, and the environment all play a role. The operator’s physical and mental condition can also contribute to unsafe actions. For example, young operators may lack the knowledge and experience to recognize hazards. Older workers may also have slower reaction times, which can make it difficult to react quickly to slippery work areas.

Reaction time is measured as the time between a stimulus and the response. It does not include the time required to move the hand. Reaction time is a critical factor in sports, where athletes need to be quick to respond to the moves of their opponents. A good reaction time is necessary to score points.

A demonstration of the speed of a PTO shaft is a great tool to demonstrate how dangerous this part of a machine can be. To demonstrate the speed, use a 7-foot sash cord tied to a sliding collar universal joint. Select a 540-rpm PTO shaft, and a three-inch diameter shield. In one second, the rotating shaft makes nine revolutions and travels 7.1 feet. However, a cordless drill does not rotate at full speed and will take at least two seconds to wrap around the string.

Standardization

The standardization of PTO shafts in tractors is a major project. The EU Machinery Directive requires the protection of operators from rotating parts, such as the PTO. This is especially important when parts are accessible, as clothing can easily be wrapped around them, resulting in an accident. To prevent such accidents, manufacturers have begun to install non-rotating guards over the PTO drive shaft. These guards comply with the current EU good practice.

The European Standard EN 12965:2003+A2:2009 specifies the safety requirements for PTO drive shafts and their guards. It also specifies safe working practices for these components. The standard was approved by CEN on 16 September 2019. It is important to follow these regulations to ensure safe operation.

In the 1980s, a movement began among agricultural engineers to standardize the PTO shaft. The movement began because the different types of PTO shafts had not been interchangeable. A common example is the Deutz-Fendt shaft, which had become a standard for tractors.

As the power for PTO drives comes from the gearbox, the counter shaft acts as the PTO outlet. Standardization of PTO speeds makes it easier for manufacturers to design equipment to meet a specified speed. For example, a thresher is expected to run at a specific peripheral velocity of the threshing cylinder, which is a function of standard PTO speeds. This also allows designers to plan pulley arrangements with the standard PTO speed in mind.

Safety chains

The PTO shaft is an integral part of a tractor or implement, so it’s essential to secure it with safety chains. These chains are welded to both ends of the shaft and serve as backup connections between the tractor and trailer coupling point. There are several types of chains available, from domestic to metric, to meet your specific needs.

Because of the high speeds of PTO shafts, it’s crucial to protect these parts from being tangled. A single fall of a PTO shaft can cause serious injury or even death. In such an unfortunate situation, safety chains can prevent such injuries. PTO shafts are also extremely dangerous because the components can become hot while they are operating.

In addition to safety chains, operators must also be aware of the hazards that can occur when working near a PTO shaft. Unsafe behaviors, such as performing repairs while operating a machine, or wearing frayed clothing can lead to serious injury or death. In addition, all users should follow the instructions on the tractor or implement they’re using. It’s also essential to use a PTO shaft for its intended purpose.

In addition to safety chains, farmers should also ensure that the PTO drive shaft is securely attached to the tractor or implement. A broken or damaged PTO guard can be just as dangerous as an unprotected shaft. In addition, a poorly fitting PTO guard may provide a false sense of security. For this reason, it’s important to use protective clothing when operating a tractor or implement powered by a PTO.

Shield

The CZPT-Co universal fit PTO shaft shield is a simple and easy to use shield that has a patented lever release. The shield comes in two sizes, the smaller diameter shield is for shafts with a diameter of 1 5/16″ to 2 1/8″ and the larger diameter shield fits shafts of 2″ to 3 1/8″. Each shield is pre-installed with an assortment of bearings. The shield’s length is measured from the end of the yoke bearing groove to the other end.

If you’ve ever tried to work on a PTO shaft, you know that it can be frustrating. A PTO shaft shield is a safety device that covers the shaft and prevents it from rotating. These shields are also designed to be easy to connect and remove. The CZPT safety clip makes it easy to connect or disconnect the shield, and locks into place to prevent it from rotating with the inner driveshaft. The CZPT material used in RPM Transmissions driveline safety shields is strong and rigid.

Another improvement of this PTO shaft shield is the bracket that supports the two-piece PTO shaft and outer shield. The bracket is shown in FIG. 2 as an angled front view. FIG. 7 is a side elevation view of the bracket mounted to the machine tongue.

editor by CX 2023-06-06

China Best Sales High Quality Km6107 Speed up Pto Gear Box for Log Splitter pto shaft cover safety chain

Product Description

High quality KM6107 speed up pto gear box for log splitter

The Gearboxes are designed for connecting gear pumps to farm tractor power take offs (PTO).Output speed of power take offs is 540rpm which can be compared with the proper running speeds of hydraulic pumps.Different input running speeds can also be suitable,provided that the PTO gearbox output speed does not exceed 3000 rpm.

Gears

Made in Steel CZPT 18 PCR M03.Stub teeth guarantee very high resistance and run very quietly.

Shafts

Made in steel CZPT 16 CRN4.They are coupled with splined gears and are designed to stand the torque values stated in the catalogue.

Lubrication

SAE 90 gear oil must be put in the pto gearbox prior to use, change the oil after the first 60-80 hours and then every 12 months or 1500 hours which ever falls first.

Maintenance

Please check the oil level via the special oil window every 50 hours.Working temperatures should not exceed 120 degrees celcius under continuos duty cycle.

Our Services

Service A: OEM and customized products are acceptable

Our company can do OEM and customized products according to the requirements of customer.

Service B: Develop new products is welcome

We have technicians and research department to make new products, if customers need us to develop new products according to sample or drawing, it is welcome.

Service C: Sourcing related producs

Our company have much experience in hydraulic and transmissions parts field, if you need other products, we can find for you.

Packaging & Shipping

Plastic bag packing for 1 piece / two pieces in 1 exporting carton / 100 cartons put on a pallet

FAQ

1.Q:Is your company a trading company or a manufacturer?

A:Our company is a trading company also a manufacturer, we have our own factory to produce gearbox, pump support..Etc

Also we distribute gear pumps, tractor machinery,dump truck pump from selected premium suppliers to meet customers’ variable demand.

2.Q:What about the quality control and warranty ?

A:”Quality first, Customers foremost”.Every piece of products is cheeked and tested strictly 1 by 1 before packing and shipping.

Our products have 1 year warranty, technical support is endless from us.

3.Q:Can you provide samples for checking and testing?

A:Yes,we provide free samples for checking the build quality and real performance of our products,the freight need to be coverd by customer.

4.Q:How can I get to your company?

A:Our company address is No.888 Huaxu Road,Xihu (West Lake) Dis. district,ZheJiang ,China

It is about 30 minutes by car from ZheJiang Xihu (West Lake) Dis.ao airport or ZheJiang Xihu (West Lake) Dis.ao Railway station.

| Type: | Forest Machine |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure |

| Material: | Aluminum |

| Power Source: | Hydraulic |

| Weight: | 5kg |

| After-sales Service: | 1 Year |

| Samples: |

US$ 70/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

The Different Parts of a PTO Shaft

Power Take-Off (PTO) shafts are an integral part of a tractor’s driveline. Without them, a tractor cannot operate. It is essential to understand the different parts of a PTO shaft, as they are crucial for the operation of your tractor. These parts are typically overlooked during routine tractor maintenance checks, but knowing more about them will help you practice on farm machinery better.

Tractor’s power take-off (PTO) shaft

A Tractor’s power take-off (or PTO) shaft transfers power from the tractor to an implement. These shafts typically rotate at speeds between 540 and 1000 rpm. A number of safety features help prevent accidental contact between the shaft and the implement.

In order to avoid this problem, tractor operators should be vigilant while operating their tractors. They should make sure that the tractor’s power take-off (PTO) shaft is shielded. These shields include a master shield for the PTO stub, a PTO integral journal shield, and an implement input connection shield. The PTO master shield is mounted on the tractor and extends over the PTO stub on three sides. It is designed to prevent collisions between the tractor and any connected machine drive shaft.

A power take-off (PTO) shaft is an important component on any tractor. It is a shaft that transmits mechanical power from a tractor to an implement or separate machine. Early PTOs used a transmission and were located at the rear of the tractor. They are now available with hydraulic or mechanical drivelines. These power take-offs transfer the tractor’s power to a secondary piece of equipment through a driveshaft.

Proper PTO shaft guards protect people from stepping on rotating shafts. The PTO should not compress fully at any point in the operating range. It should have several inches of overlap at the maximum operating extension. A PTO guard should be positioned properly for each machine.

Despite these benefits, there are still many risks associated with PTO shafts. These powerful and potentially dangerous pieces of machinery can cause severe injury if not used safely. Luckily, proper installation of safety shields can reduce the risk of injury.

Types

PTO shafts come in a variety of different shapes, sizes, and materials. The most common types are square and round, but there are also star-shaped and trilobed types. While the star-shaped type is a typical North American design, the trilobed and lemon-shaped varieties are typically German or Italian. Typically, the lemon-shaped ones are made of an alloy called ‘Lemon Yellow.’ In some cases, the shaft will come with snap rings.

Different manufacturers use various materials for their PTO shafts. The tube of a welded drive shaft must be strong enough to handle the force exerted by the PTO. There are many different materials available, but some are stronger than others. Before choosing the type of drive shaft that is right for your machine, make sure that you know the exact measurements of your driveline.

When deciding between different types of PTO shafts, you must also consider the materials that will be used for your particular application. While splines are the most common material for PTO shafts, you can find various types that have different uses. Carbon steel is malleable and has a low carbon content, which makes it more reliable. A ferrous steel is more durable and contains metals like nickel, chromium, and molybdenum, which make it a great alternative to carbon steel.

A PTO gearbox input shaft extends between the PTO gearbox and the PTO clutch. It is mounted with a toothed wheel 8. An inductive sensor 9 on the shaft outputs a pulsed electronic signal based on the rotational speed of the shaft. These pulsed signals are called inductive speed sensors.

Rotation direction

The PTO shaft is a critical part of the power take-off of a farm tractor. It allows the tractor to transfer power from the engine to an implement such as a mower or other garden equipment. The rotation direction of the PTO shaft depends on the type of implement. Some implements only accept rotation in one direction, while others require rotation in both directions.

Safety chain

One of the best ways to protect your PTO shaft is to use a safety chain. A safety chain is a chain that is attached to the PTO shaft, and it prevents the plastic shield from spinning on the shaft. This chain should be fastened to a suitable point on your machine or tractor. It should not be attached to the lower lift arms or the U-guard.

One of the best ways to protect your PTO shaft is to use a safety chain. A safety chain is a chain that is attached to the PTO shaft, and it prevents the plastic shield from spinning on the shaft. This chain should be fastened to a suitable point on your machine or tractor. It should not be attached to the lower lift arms or the U-guard.

PTO shafts can be very dangerous if they are not guarded. They can rotate as high as 1000 rpm and could seriously injure you. It is also important to ensure that the PTO shaft guard is fitted correctly, and that the tractor is turned off before working on it. In addition, avoiding wearing loose clothing when working around a PTO shaft can help protect your life.

Another way to protect the PTO shaft is to shield the IID shaft. This can be done by using shielding over the straight part of the shaft, the PTO connection, or the Implement Input Connection. A protruding bolt or pin can catch clothing and snag it. If not shielded, the clothing can wrap around the shaft, trapping the person against it.

A good safety chain should be positioned between the tractor and the PTO shaft. The chain should be at least 50 mm wider than the PTO shaft, and should be in good condition. It should cover the entire length of the PTO shaft from the tractor to the first bearing. The PTO shaft must also be fitted with the correct bearing ring. It is also vital to ensure that the PTO guard does not bend or break, as this could result in damage to the PTO shaft.

Shield

A PTO shaft shield protects the PTO shaft from possible impacts. It is typically made of plastic, but can also be made of metal. These shields are easy to damage, and are therefore preferably made of a durable material. The shields are held in place with brackets. The shields are made with two parts: an inner shield and a protective sleeve.

A PTO shaft shield protects the PTO shaft from possible impacts. It is typically made of plastic, but can also be made of metal. These shields are easy to damage, and are therefore preferably made of a durable material. The shields are held in place with brackets. The shields are made with two parts: an inner shield and a protective sleeve.

An improvement to the PTO shaft shield is a bracket that supports both the outer and PTO shaft. It is shown in conjunction with a towed machine in FIGS. 2 and 7. FIG. 7 is a side elevation of the bracket mounted to the tongue of the machine. This shield is designed to prevent the PTO shaft from becoming damaged during the towed process.

The main risk associated with PTO mishaps is entanglement, which can result in serious injuries. If a shaft separates from a tractor, it can strike nearby workers or people. Proper maintenance can minimize the risk of entanglement and save lives. Thankfully, equipment manufacturers have made huge strides in reducing the risk of these accidents. Operators should always make sure that the PTO shaft shield is in place to avoid the risk of entanglement.

In addition to preventing entanglement, a PTO shaft shield also helps protect the universal joints that are mounted on the PTO shaft. The shield is made of plastic or steel. It is typically shaped like an inverted U and covers both the top and sides of the shaft. A detachable PTO shaft shield is also available.

As with all parts of a PTO driveline, the PTO shaft shield should be maintained to prevent damage to the bearings. It is necessary to inspect the shield and replace it whenever it becomes damaged. PTO equipment is often used outdoors, and it is frequently exposed to crop debris, rust, and dirt that can affect the bearings. Proper maintenance will extend the equipment’s lifespan and reduce maintenance costs.

editor by CX 2023-05-30

Best shop made in China – replacement parts – PTO shaft manufacturer & factory Worm one piece driveshaft dodge 3500 Wheel Gear Wheel Motor Gear Set Diameter Shaft Pin Bore Tooth for Speed Reduction Transmission Parts High Quantity Good Price Industrial Manufacturer Gears with ce certificate top quality low price

We – EPG Group the largest agricultural gearbox and pto manufacturing facility in China with 5 distinct branches. For far more details: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

boat travel shaft The what course pto shaft do i want firm 2002 dodge ram generate shaft covering pto shaft restore 88,000 ford 8n pto shaft substitute square rhino bush hog sellers meters, tractor pto adapters has pto shaft for yanmar tiller advanced pto driveline parts gear pto shaft with slip clutch and powerful specialized strength, this sort of as the numerical handle machine instruments and machining facilities, CAD/CAM method, industrial robotic and so on. Our business is found in XiHu HangZhou Zhejiang Province. T

Worm Wheel Gear Wheel Motor Gear Set Diameter Shaft Pin Bore Tooth for Velocity Reduction Transmission Elements Higher Quantity Excellent Cost Industrial Manufacturer Gears

The mating worm gear mounts on a specialized Metal 1/4″ D-Bore Barrel Hub for Worm Equipment to develop a reputable junction amongst the equipment and the shaft it is turning. The worm and the worm equipment are made so that you can operate them .75″ aside from one one more the identical spacing you’ll locate on Ever-power and other parts in the create method. Aside from the massive reduction in velocity and the increase in torque, these worm gears will lock in place when at rest so you do not have to fear about an exterior force backdriving the system driving them.

Best China manufacturer & factory T in Quebec City Canada Series 90 Degree Sprial Bevel gear reducer gearbox helical bevel speed gearbox reduction gear motor harmonic gear With high quality best price

Our AdvantagesProducts Large quantity in Inventory, No MOQ required We comply with all the worldwide requirements, this sort of as ISO9001 and TS16949 requirements.

Overview

Swift Details

- Applicable Industries:

-

Developing Substance Retailers

- Gearing Arrangement:

-

Bevel / Miter

- Output Torque:

-

Up to 3378Nm

- Enter Speed:

- In our business we are conscious of the relevance of the users’ basic safety. That is why our PTO’s are developed in accordance to lawful laws and European directives and bear the CE signal. A key aspect for safety assurance is the accession in the products’ improvement section. By all means, the users’ understanding about the right use of a PTO travel shaft is crucial. This implies, that every single users’ duty is to read through and adhere to the basic safety directions.

750-1500rpm

- Output Velocity:

-

three~1450r/min

- Area of Origin:Zhejiang, China

- Brand Identify:

-

OEM

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

C&U

In comparison to other types of gears, worm gears are exclusive and have extremely exclusive qualities and uses. This put up will target on the positive aspects of worm gears. For a record of common worm equipment apps, remember to see worm gear abilities.

- gear precision grade:

-

din four

Source Capability

- Offer Potential:

- 1000 Device/Models per Month

Packaging & Delivery

- Packaging Information

- Common wooden scenario

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Quantity(Bins) 1 – one >1 Est. Time(days) 20 To be negotiated

On the web Customization

Product Description

T Sequence 90 Diploma Sprial Bevel gear reducer gearbox helical bevel velocity gearbox reduction equipment motor harmonic gear

Advantage:

-Self-locking ability

-Can be pushed immediately by motor or other power or handbook

-Can be tailored in accordance user’s demand

-Compact configuration, modest measurement, light-weight

-Convenient installation, versatile procedure

-Large dependability and security

-Lengthy provider life

-More relationship form and so on.

Screw jak is applied to all fields for lifting or pulling, this kind of as Aircraft upkeep system, Solar plate, equipment, metallurgy, water conservancy, medical treatment method, chemical business, culture and hygienist and many others.

Specs:

one.Tseries spriWe warmly welcome the pals from all the entire world!al bevel equipment reducer with various sorts are standardized

2.all ratio of 1:1,1.5:twelve:twelve.5:13:fourteen:1and 5:1 are genuine types,

three.average performance is 98%.

|

Solution Name |

T series Spiral Bevel Gearbox |

|

product no. |

T2, T4, T6, T7, T8, T10, T12, T16, T20, T25 |

|

Ratio |

one:1, 1.5:1, 2:1, 2.5:1,3:1,4:1,5:one |

|

gear Material |

higher grade synthetic diamond 50CrMnT |

|

Equipment Processing |

Grinding end by HOFLER Grinding Equipment, Precision quality : DIN 4 |

|

spindle |

high purity metal alloy 40Cr piece |

|

Sound Check |

Bellow 65dB |

|

Warranty |

1 year |

Goods Show

Good quality manage

Organization data

Packing & Shipping and delivery

Packing Specifics : Standard carton/Pallet/Common wood situation

Shipping and delivery Specifics : 15-thirty working times upon payment

FAQ

Q1: What information should I tell you to validate the item?

A: Design/Size, Transmission Ratio, Shaft instructions & Get amount.

Q2: What can i do if I do not know which one I need to have?

A: Do not fear, Send as much information as you can, our group will assist you uncover the appropriate one you are hunting for.

Q3:What is your solution warrenty time period?

A:We offer one yr warrenty since the vessel departure date remaining China.

This fall: What is your terms of payment ?

A: thirty% T/T in progress ,balance ahead of shippment.

If you have another issue, pls really feel free of charge to contact us.

Make contact with US

Best China manufacturer & factory Manufacturer in Birmingham United Kingdom wholesale gear stepless cone disc transmission regulator motor speed reducer variator for industry equipment With high quality best price

We are aiming to meet the demands of the clients around the world.. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- ITEM NO:

-

SYF

- Model Number:

-

MB/JWB

- Product name:

-

stepless reducer

- Color:

-

Customzie

- Application:

-

Power Tranmission

- Material:

-

Aluminium Alloy

- Ratio:

-

0.5-6000

- Mounting Position:

-

Horizontal (foot Mounted)

- Certificate:

-

ISO9001

- Efficiency:

-

70-85%

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 5 >5 Est. Time(days) 15 To be negotiated

Online Customization

EPG major production is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories.

Product Description

MB/JWB stepless speed changer after years of practice in use, proved in a large number of CVT family, with a unique style, because the of product design reasonable structure, easy operation, transmission stability and other characteristics, it is widely used in food Machinery, printing, papermaking machinery, rubber, plastic machinery, ceramic machinery, pharmaceutical machinery and a variety of work in the production process requirements of the process parameters change and speed of continuous changes in the occasion, but also with the new product trial process to explore the best machine Working speed.

Main Features

1. stepless speed control speed, speed control accuracy of 0.5-1 turn, which is the leader of similar products.

2,.the height range of large speed range Rb = 5.

3,.this of transmission parts are all strictly handled, precision machining, grinding, contact and lubrication performance is good, so smooth operation, low noise, long service life.

4,.MB transmission is the biggest feature is effective in a variety of gear reducer, cycloid reducer, worm gearbox, gear motor combined use, thereby increasing the output torque and achieve a variety of different occasions the lowest And the maximum output speed, with good adaptability.

5. the output torque and power of the transmission with the number of changes in the number of changes, with variable torque, variable power of the mechanical characteristics.

Our Company

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Facilities Co. Ltd

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Equipment Co., Ltd.is a gift enterprise integrating development, design, production and sales,Main promoting products include reducer motor,water pump,construction machinery and parts,bearings,hardware and electrical equipment,plastic products,Labour protection appliance.Our company always follow the operation concept which contains people-oriented, innovation as the soul,be prepared for ….

Application area

Certifications

Sales territory

Packing & Delivery

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a manufacturer in ZheJiang China.welcome to our factory to have a visit.

Q2: How we select models and specifications?

A:You can email us the series name & code (for example: WJ series worm gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures Worm gears are typically manufactured by hobbing with a hob or cutting tool very similar to the worm that the gear mates with. The worm may be turned, hobbed, milled, or ground.or drawings, it is better.

Q3: How is your price? Can you offer any discount?

A: We will give the best price we can base on your needs and the quantities.

Q4: How long should I wait for the feedback after I send the enquiry?

A: Within 12 hours.

Q5: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q6: What industries are your gearboxes being used?

A:Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Contact us

Mobile: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Add:No.789 ShenHua Road, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Facilities Co. LtSlip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST MODELS three different types of PTO in operation: a non shear, shear pin and slip clutch — the last being the most expensive. Implement end of non shear (r) and shear type (l) Non shear: this is a solid yoke to yoke set up and used with the expectation that certain equipment will not encounter any sudden stops. I figure that the finishing mower does not need a shear set up as the blades will slip to a degree being belt driven and my other mower, the flail mower, is extremely forgiving in its design.d.

Best China manufacturer & factory china supplier Manufacture Right angle Planetary gear set unit box speed reducer for concrete mixer trucks With high quality best price

EPG was awarded with “famous product of Zhejiang Province” and “famous brand of Zhejiang Province”.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Pole:

-

one two three stage

- Ratio:

-

2.8-2000

- Housing Material:

-

Cast Iron

- Material:

-

20CrMn

- Working temperatur–Driven (outer) yoke same as drive yoke but is mounted on the implement. There are two types of shafts, domestic and metric, which are identifiable by their shapes. Domestic are generally one of four shapes: round, square, rectangle or splined. Metric are: bell, star or football shaped. In either case the primary (front) shaft is the same shape as the secondary shaft, only bigger so that the secondary shaft fits inside. This allows a telescoping effect to take place when the implement is raised on the 3 pt. or during a turning movement such as a bailer. All shafts have to be sized before use. Attach the implement to the 3 pt. and raise and support it. Attach the proper end to the tractor and attempt to attach the other to the implement. If the shaft is too long trim one of the shafts with a hack saw and try it again until it fits. This allows for the implement to be raised without binding. The shafts should overlap as much as allowed.e:

-

-40~45℃

- Application:

-

Right angle Planetary gear set unit for concrete mixer trucks

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

92%~96%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Red

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 10 >10 It was born in 1997, and is the fruit of the merger of different gearboxes brands. From the first products, it inherited a philosophy based in quality, profitability and technical rigor. EPG is present in all european market, through a complete distribution chain consisting of each market’s principal actors. Est. Time(days) 15 To be negotiated

Online Customization

Product Description

NGW / P Series Planetary Gear Reducer

Sun Gear, Planetary Gear,Internal GearRing,Staging Gear

Chinese Speed Reducer widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

NGW Series Mini Planetary Gearbox for concrete mixer including one-stage,two-stage and three-stage, it is suitable for the required speed ratio≤1500r/min, working temperature around -40~45℃, two runs alternative in direction.

P series Mini Planetary GUnder the guidance of managerial sense of “Serving agriculture, scoring a success through quality of products and honesty in business”, our products have been trusted by clients and have gained a larger share of market.earbox for concrete mixer including two-stage and three-stage, it is suitable for the required speed ratio 25-4000, the ratio will be larger in combination with R,K series reducer.

Feature:

-

Modular design,right angle planetary gear box for slewing

-

Material: Cast iron HT 250 for housing; 20CrMnTi for Gear and Shaft

-

Sun gear, Planetary gear and Ring gear all c which will improve the efficiency and service life of the reducer.

-

Input mode: coaxial input, helical gear input, bevel-helical gear input

-

Output mode: internal involute spline, hollow shaft with shrink disk, external involute spline, solid shaft with flat key.Gearbox Factory Coaxial planetary gear speed reducer for travelling gear.

-

Mounting mode: Horizontal,Vertical,Torque-arm.planetary motor gearbox for concrete mixer

Specification

Mounting Diamensions of Planetary gear set unit:

(please contact us for more types & model)

| NGW Series Specification | ||||||||||||

| Size | NGW 11 | NGW 21 | NGW 31 | NGW 41 | NGW 51 | NGW 61 | NGW 71 | NGW 81 | NGW 91 | NGW 101 | NGW 111 | NGW 121 |

| Input Speed rpm |

600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 |

| Input power rating(kw) |

2.7-38.6 | 3.9-57.3 | 5.5-89.4 | 7.6-126 | 10.8-179 | 15-249 | 21.7-336 | 31.1-472 | 43.7-668 | 74.2-680 | 85-964 | 124-1314 |

| Ratio | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 |

| Permissible torque N.m |

420-1600 | 590-1600 | 820-228- | 1150-3240 | 1580-4680 | 2270-6490 | 3160-9050 | 4330-12490 | 6000-17660 | 8400-24980 | 11370-35720 | 17020-50420 |

Model selection of right angle planetary gear box for slewing:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.planetary motor gearbox for concrete mixer.modular construction high torque planetary gearbox components.Gearbox Factory Coaxial planetary gear speed reducer for travelling gear.Chinese Manufacture Right angle Planetary gear set unit box speed reducer for concrete mixer trucks.

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

Technology

Chinese Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. Mini Planetary Gearbox for concrete mixer. right angle planetary gear box for slewing.planetary motor gearbox for concrete mixer.modular construction high torque planetary gearbox components.Manufacture Right angle Planetary gear set unit box speed reducer for concrete mixer trucks.

Packaging & Shipping

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

K China helical bevel gearbox drive reducer mechanical speed variator gear reducer gearbox for concrete mixer – Supplier Manufacturer wholesaler Factory

EPG – a single of the greatest transmission manufacturing facility in China, main items: worm geared motors, agricultrual gearbox, planetary equipment drive, helical,screw, beve gears and spare parts and agricultural areas manunfacuter in ChinaFor more info.: Cellular/Whatpp: +8613083988828

Helical China design electric motor small gear right angle high speed reducer reduction worm gearbox suppliers – Supplier Manufacturer wholesaler Factory

For far more info.: Mobile/Whatpp: +8613083988828

Slip clutch: this kind utilizes a slip clutch on the pushed finish yoke which is comprised of 3 steel plates in line held collectively with a collection of bolts with springs under the nuts. The concept listed here is that when you tighten the nuts the force is enhanced on to the centre plate which when set up for the load will enable the shaft to turn and the put into action to stall, absorbing the shock load. As mine is rated from 20-40 hp and I’m operating a seventeen hp I had to make alterations to established it up. Via trial and mistake I decided that I had to eliminate 50 percent the rigidity bolts and springs and back off the remainder nuts to least in purchase for the clutch to “slip” prior to stall on the tractor.Our goods are exported to all above the planet, also distributors locates around the world , the products are commonly employed in boating engineering, petroleum, chemical industry, wind electrical power, hydropower, thermal energy, mining, large market, servicing of bridge development and so forth.We examine each and every piece of bearing by ourselves prior to supply.Below the guidance of managerial feeling of “Serving agriculture, scoring a good results via top quality of products and honesty in organization”, our items have been trustworthy by customers and have gained a bigger share of market.

Overview

Swift Information

- Relevant Industries:

-

Development works

- Gearing Arrangement:

-

Worm

- Output Torque:

-

15~1700Nm

- Enter Velocity:

-

500~2800/min

- Output Speed:

-

5~560/min

- Brand Name:

-

OEM

- Item name:

-

correct angle substantial speed gearbox reduction worm gearbox suppliers

- Application:

-

Meals Stuff, Ceramics, Chemical, Packing, Dyeing,Wooden doing work, Glass.

- Color:

-

Blue(RAL5010)/Silver gray (RAL9022) Or On Request

- Ratio:

-

5,7.5,10,15,20,25,thirty,forty,fifty,60,eighty,100.

- Guarantee:

-

one Calendar year

Supply Capability

- Supply Capacity:

- 36000 Piece/Parts for every Month

Packaging & Delivery

- Packaging Specifics

- Transparent box packaging, or shade box packaging, it also can be tailored.

- Port

- Ningbo/Shanghai

Online Customization

Helical layout electric powered motor little gear proper angle high speed gearbox reduction worm

gearbox suppliers

Q1.How to decide on a gearbox which fulfills our requirement?

A1: You can refer to our catalogue to pick the gearbox or we can assist to choose when you give

the specialized info of output torque, output velocity and motor parameter and many others.

Q2.How is your value? Can you provide any price cut?

A2: We will give the ideal price tag we can base on your requirements and the quantities.

Q3.Do you provide any going to?

A3: Sure! We sincerely invite you to visit us! We can pick you from airport, railway station and so on.

Also, we can organize housing for you. Make sure you permit us know in advanced.

This autumn.When is the ideal time to get in touch with you?

A4: You can get in touch with us by email any time, we will reply you as before long as attainable.

Q5.How lengthy will it take for the guide time?

A5: For our regular model, you should refer to the diverse product webpages to check out the lead time.

For the OEM/ODM products, make sure you speak to us for additional data.

EPG – one particular of the largest transmission factory in China, main products: worm geared motors, agricultrual gearbox, planetary gear drive, helical,screw, beve gears and spare parts and agricultural components manunfacuter in China /For far more details.: Cell/Whatpp: +8613083988828